Giới thiệu về máy đóng gói vỉ

Máy đóng gói vỉ đã trở nên thiết yếu trong ngành dược phẩm, thực phẩm và hàng tiêu dùng. Nhưng điều gì khiến chúng quan trọng đến vậy? Những máy này cung cấp giải pháp đóng gói hiệu quả, chính xác và đảm bảo vệ sinh. Không giống như các phương pháp đóng gói truyền thống, một máy đóng gói dạng vỉ đảm bảo từng sản phẩm được đóng gói riêng lẻ, mang lại khả năng bảo vệ khỏi sự nhiễm bẩn, độ ẩm và hư hại vật lý. Các nhà sản xuất dựa vào những máy móc này như thế nào để duy trì chất lượng sản phẩm khi mở rộng quy mô sản xuất? Tính linh hoạt và độ tin cậy của máy đóng gói vỉ khiến chúng trở thành công cụ không thể thiếu trong sản xuất hiện đại.

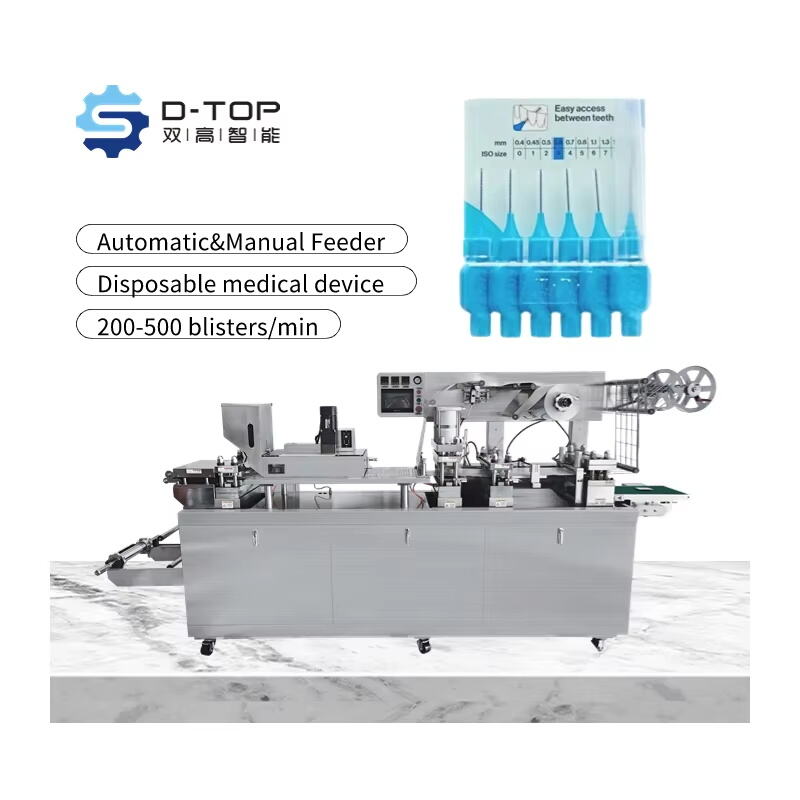

Cách Hoạt Động Của Máy Đóng Gói Vỉ

Cơ Chế Cơ Bản

A máy đóng gói dạng vỉ hoạt động bằng cách tạo ra các khoang hoặc túi trong một tấm nhựa và sau đó hàn kín chúng bằng vật liệu đậy nắp, thường là lá nhôm. Sản phẩm được đặt vào các khoang này, sau đó được bịt kín để bảo vệ các vật phẩm bên trong. Quy trình này bao gồm việc gia nhiệt, tạo hình, đóng gói và hàn kín trong một luồng làm việc liên tục. Điều này đảm bảo độ chính xác và hiệu quả, đặc biệt khi xử lý các đợt sản xuất với sản lượng lớn.

Tự động hóa và hiệu quả

Tự động hóa trong máy đóng gói vỉ giúp giảm lao động thủ công và tăng năng suất. Cảm biến và hệ thống điều khiển máy tính giám sát quá trình vận hành, đảm bảo tính nhất quán trong việc hàn seal và giảm lãng phí. Doanh nghiệp có thể được lợi gì từ tự động hóa như vậy? Bằng cách cải thiện tốc độ, độ chính xác và giảm sai sót của con người, các nhà sản xuất có thể đáp ứng các tiêu chuẩn ngành nghiêm ngặt trong khi vẫn đảm bảo hiệu quả về chi phí.

Các loại Máy đóng gói Blister

Máy Tạo Hình Nhiệt và Máy Tạo Hình Lạnh

Máy đóng gói vỉ nói chung được chia thành hai loại chính: tạo hình nhiệt và tạo hình lạnh. Máy tạo hình nhiệt sử dụng tấm nhựa được đun nóng để tạo các rãnh, sau đó rãnh được điền sản phẩm và hàn kín. Trong khi đó, máy tạo hình lạnh sử dụng vật liệu gốc nhôm và không cần dùng đến nhiệt. Loại nào phù hợp với sản phẩm của bạn? Máy tạo hình nhiệt lý tưởng cho các loại viên nén và viên nang, trong khi máy tạo hình lạnh cung cấp khả năng bảo vệ chống ẩm vượt trội cho các sản phẩm nhạy cảm.

Máy Đơn Trạm và Máy Đa Trạm

Máy đóng gói vỉ một trạm thực hiện các bước tạo hình, đổ đầy và hàn kín theo trình tự tại một trạm duy nhất, phù hợp cho sản xuất quy mô nhỏ. Ngược lại, máy nhiều trạm thực hiện mỗi bước ở các trạm riêng biệt, cho phép tốc độ sản xuất nhanh hơn và hiệu suất cao hơn. Việc lựa chọn cấu hình phù hợp phụ thuộc vào khối lượng sản xuất, loại sản phẩm và ngân sách.

Lợi ích của việc sử dụng máy đóng gói vỉ

Tăng cường bảo vệ sản phẩm

Một lợi thế lớn của máy đóng gói dạng vỉ là bảo vệ sản phẩm. Việc hàn kín từng ô giúp ngăn chặn tiếp xúc với không khí, độ ẩm và các chất gây ô nhiễm, kéo dài thời hạn sử dụng của sản phẩm. Đối với dược phẩm sẢN PHẨM điều này rất quan trọng, bởi bao bì không đúng cách có thể làm giảm hiệu quả và ảnh hưởng đến an toàn sản phẩm.

Hiệu quả về chi phí và thời gian

Dù chi phí ban đầu có thể cao, nhưng máy đóng gói vỉ giúp tiết kiệm chi phí trong dài hạn. Tự động hóa giảm chi phí nhân công, hạn chế sai sót và tăng năng suất. Điều này ảnh hưởng thế nào đến lợi nhuận doanh nghiệp? Chu kỳ sản xuất nhanh hơn và giảm thất thoát giúp cải thiện biên lợi nhuận và ổn định nguồn cung.

Tuân thủ và khả năng truy xuất

Nhiều ngành công nghiệp phải tuân thủ các quy định nghiêm ngặt. Máy đóng gói vỉ có thể in mã lô hàng chính xác và truy xuất nguồn gốc, đảm bảo phù hợp với các tiêu chuẩn ngành. Khả năng này đặc biệt quan trọng trong ngành dược phẩm, nơi việc truy xuất nguồn gốc là thiết yếu đối với việc thu hồi sản phẩm hoặc kiểm toán chất lượng.

Lựa chọn Máy Đóng Gói Vỉ Phù Hợp

Đánh giá Nhu cầu Sản phẩm của Bạn

Trước khi chọn máy đóng gói vỉ, hãy cân nhắc hình dạng, kích thước và độ nhạy cảm của sản phẩm. Các loại viên nén, viên nang hoặc hàng tiêu dùng nhỏ có thể yêu cầu các loại máy khác nhau. Làm thế nào để lựa chọn máy phù hợp với nhu cầu sản xuất? Hãy đánh giá kích thước sản phẩm, khối lượng và vật liệu đóng gói để xác định cấu hình phù hợp nhất.

Đánh Giá Các Tính Năng Của Máy

Máy đóng gói vỉ hiện đại đi kèm với nhiều tính năng khác nhau, bao gồm cấp liệu tự động, niêm phong điều chỉnh được và hệ thống kiểm soát chất lượng tích hợp. Việc đầu tư vào các máy có tính năng tiên tiến có thể cải thiện hiệu suất và đảm bảo đóng gói chất lượng cao. Bạn ưu tiên tính năng nào? Hãy tập trung vào những tính năng phù hợp với yêu cầu sản xuất và khả năng mở rộng lâu dài của bạn.

Xem xét ngân sách và bảo trì

Chi phí là yếu tố quan trọng khi lựa chọn máy đóng gói vỉ. Tuy nhiên, cần cân bằng giữa giá ban đầu với chi phí bảo trì và vận hành dài hạn. Những máy có bộ phận đáng tin cậy và các tùy chọn dịch vụ dễ tiếp cận sẽ giảm thời gian dừng máy và nâng cao hiệu quả đầu tư.

Lời Khuyên Bảo Trì và Vận Hành

Vệ sinh và kiểm tra thường xuyên

Việc bảo trì máy đóng gói vỉ đòi hỏi phải vệ sinh định kỳ để ngăn ngừa nhiễm bẩn và sự cố cơ học. Kiểm tra các bộ phận niêm phong, con lăn và bộ điều khiển nhiệt độ để đảm bảo hoạt động ổn định. Bảo trì đúng cách giúp kéo dài tuổi thọ máy móc và đảm bảo an toàn.

Đào tạo và Vận hành chuyên nghiệp

Người vận hành phải được đào tạo để vận hành máy đóng gói vỉ thuốc hiệu quả. Hiểu rõ cài đặt máy, xử lý lỗi và duy trì tiêu chuẩn vệ sinh là điều cần thiết để vận hành trơn tru. Đầu tư vào đào tạo giúp giảm thiểu lỗi và cải thiện năng suất.

Ứng Dụng Trong Các Ngành Công Nghiệp

Ngành Dược phẩm

Ngành công nghiệp dược phẩm phụ thuộc rất nhiều vào các máy đóng gói vỉ để đóng gói thuốc viên, nang và thiết bị y tế. Bao bì kín bảo vệ sản phẩm khỏi độ ẩm và nhiễm bẩn, đảm bảo an toàn cho người sử dụng. Các công ty được lợi gì từ điều này? Đóng gói chính xác và khả năng truy xuất nguồn gốc giúp tuân thủ các tiêu chuẩn quy định.

Thực phẩm và Hàng tiêu dùng

Máy đóng gói vỉ cũng được sử dụng rộng rãi cho các sản phẩm bánh kẹo, thiết bị điện tử và đồ tiêu dùng nhỏ. Bao bì riêng lẻ giúp bảo vệ các sản phẩm dễ vỡ hoặc dễ hư hỏng đồng thời cải thiện tính thẩm mỹ. Điều gì làm cho phương pháp này trở nên có giá trị? Tăng tính hấp dẫn trưng bày trên kệ và giảm hư hại trong quá trình vận chuyển.

Xu hướng Tương lai trong Công nghệ Đóng gói Vỉ

Máy thông minh và kết nối

Những tiến bộ trong IoT và AI đang thay đổi các máy đóng vỉ thuốc. Các máy thông minh có thể giám sát sản xuất theo thời gian thực, dự đoán nhu cầu bảo trì và tối ưu hóa hiệu suất. Điều này ảnh hưởng đến các nhà sản xuất như thế nào? Thời gian vận hành tăng, kiểm soát chất lượng tốt hơn và các thông tin dựa trên dữ liệu giúp hoạt động sản xuất có lợi nhuận cao hơn.

Vật liệu thân thiện với môi trường

Tính bền vững đang trở thành ưu tiên trong ngành bao bì. Các máy đóng vỉ thuốc đang được điều chỉnh để sử dụng vật liệu có thể tái chế và phân hủy sinh học. Liệu các nhà sản xuất có thể duy trì khả năng bảo vệ sản phẩm trong khi giảm tác động môi trường? Có - vật liệu đổi mới cho phép vừa bền vững vừa an toàn.

Câu hỏi thường gặp

Máy đóng gói vỉ thuốc có thể xử lý những sản phẩm nào?

Máy đóng vỉ thuốc rất linh hoạt và có thể đóng gói được các loại viên nén, nang, thiết bị điện tử nhỏ, mỹ phẩm và các sản phẩm kẹo.

Làm thế nào để chọn đúng máy đóng vỉ phù hợp với doanh nghiệp của bạn?

Đánh giá kích thước sản phẩm, khối lượng sản xuất, mức độ bảo vệ cần thiết và các tính năng tự động hóa để lựa chọn một chiếc máy phù hợp với nhu cầu của bạn.

Bảo trì máy đóng gói vỉ cần thực hiện những công việc gì?

Vệ sinh định kỳ, kiểm tra các bộ phận hàn kín, bôi trơn và đào tạo vận hành viên là những yếu tố quan trọng để đảm bảo hiệu suất ổn định và độ bền của thiết bị.

Máy đóng gói vỉ có giúp cải thiện hiệu suất sản xuất không?

Có, máy đóng gói vỉ tự động giảm thiểu lao động thủ công, hạn chế sai sót và tăng năng suất, từ đó nâng cao hiệu quả sản xuất và tiết kiệm chi phí.

Mục Lục

- Giới thiệu về máy đóng gói vỉ

- Cách Hoạt Động Của Máy Đóng Gói Vỉ

- Các loại Máy đóng gói Blister

- Lợi ích của việc sử dụng máy đóng gói vỉ

- Lựa chọn Máy Đóng Gói Vỉ Phù Hợp

- Lời Khuyên Bảo Trì và Vận Hành

- Ứng Dụng Trong Các Ngành Công Nghiệp

- Xu hướng Tương lai trong Công nghệ Đóng gói Vỉ

- Câu hỏi thường gặp