Stainless steel is a commonly used material in many industries due to its unmatched corrosion resistance and excellent durability. Among them, 304 and 316 stainless steel are the most common and widely used. These are also the two main materials selected for the production of tablet presses.

Ingredients of stainless steel:

Stainless steel is an alloy of iron and carbon that uniquely combines durability, practicalityand aesthetics. And then assigns its unique features by adding other elements.

Table: Common elements in stainless steel and their functions

| Element | Percentage | Main function |

| Iron | 50% | substrate |

| Chromium | 10.5, 30% | has anti-fouling, anti-rust and anti-corrosion capabilities |

| Carbon | <2% | increases hardness but decreases toughness |

| Nickel | 0.35% | enhances corrosion resistance and transforms the structure from ferrite to austenite |

| Molybdenum | 0.70% | improved resistance to chloride corrosion |

Element Percentage Main function

Iron 50% substrate

Chromium 10.5, 30% has anti-fouling, anti-rust and anti-corrosion capabilities

Carbon <2% increases hardness but decreases toughness

Nickel 0.35% enhances corrosion resistance and transforms the structure from ferrite to austenite

Molybdenum 0.7% improved resistance to chloride corrosion

304: Most common grade; excellent molding and welding properties.

316: Contains molybdenum, with better corrosion resistance, especially for chloride.

410: A hard, solid but less malleable variant of martensite.

304 Stainless steel

The 304 is the most widely used stainless steel, is the "main force" of the stainless steel family, it is the perfect combination of corrosion resistance, weldability

and formability. Its main components are chromium (Cr) and nickel (Ni), containing 18% chromium and 8% nickel.

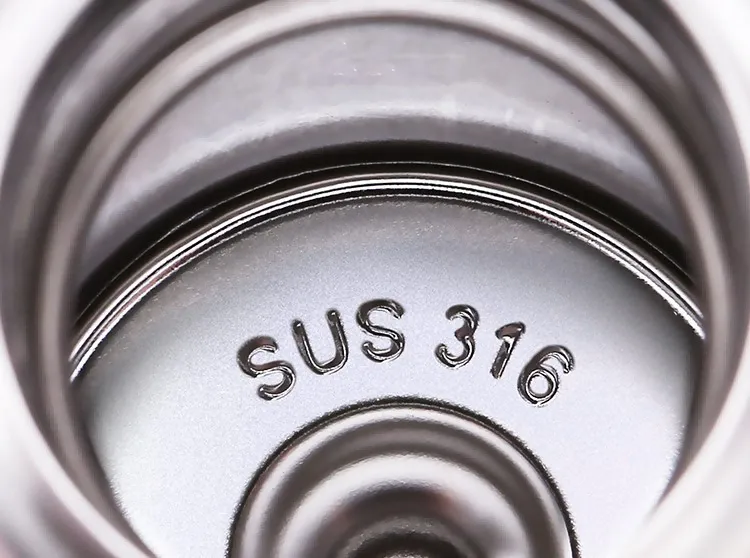

316 Stainless steel

In essence, both 304 and 316 belong to austenitic stainless steel, meaning that they have similar basic elements. However, small changes in their composition

create substantial differences.

Compared with 304,316 adds 2% of molybdenum, which is used to enhance the corrosion resistance of stainless steel, so that it can resist chloride erosion.

Therefore, 316 stainless steel has better resistance to seawater, brine and other corrosive media than 304 stainless steel.

Fields of application

316 stainless steel is widely used in medical equipment, chemical equipment and other fields because of its excellent corrosion resistance and stability.

And 304 stainless steel, as a widely used food grade material, is more used in cooking utensils, tableware and some light industrial products.

Stainless steel selection

The price of the 316 stainless steel will usually be higher than the 304. This is mainly because the 316 stainless steel adds molybdenum in the production process,

which increases its production cost. Therefore, in the selection of materials, the products made by the tablet press are not corrosive, such as candy tablets,

ordinary tablets are more recommended 304 stainless steel, if there is a certain corrosive,

such as salt tablets, disinfection tablets, etc.,need to use 316 stainless steel.

430: Common iron body material.

2205: Dual-phase stainless steel is known for its high strength and corrosion resistance.

Copyright © 2026 Nanjing D-Top Pharmatech Co.,Ltd. All rights reserved. - Privacy policy