Manufacturing businesses across industries are increasingly recognizing the transformative impact of automated filling solutions on their production lines. The modern liquid filling machine represents a significant advancement in packaging technology, offering unprecedented levels of precision, efficiency, and reliability that traditional manual methods simply cannot match. As market demands continue to evolve and competition intensifies, companies are seeking ways to optimize their operations while maintaining the highest quality standards for their products.

The integration of automatic filling technology has revolutionized how manufacturers approach liquid packaging processes. From pharmaceuticals and cosmetics to food and beverages, businesses are discovering that investing in advanced liquid filling machine technology delivers measurable returns through improved productivity, reduced waste, and enhanced product consistency. These sophisticated systems have become essential components of modern production facilities, enabling companies to scale their operations while maintaining strict quality control measures.

Enhanced Production Speed and Throughput

The most immediate advantage of implementing an automatic liquid filling machine is the dramatic increase in production speed and overall throughput capacity. Modern automated systems can fill hundreds or even thousands of containers per hour, far exceeding the capabilities of manual filling operations. This enhanced speed allows manufacturers to meet growing demand without proportionally increasing labor costs or production time.

Consistent High-Speed Performance

Unlike manual processes that are subject to human limitations and fatigue, an automatic liquid filling machine maintains consistent performance throughout extended production runs. These systems are engineered to operate continuously at optimal speeds, eliminating the natural variations in pace that occur with manual filling methods. The consistent high-speed performance ensures that production schedules can be met reliably, reducing the risk of delays and improving overall operational efficiency.

Advanced servo-driven technology in modern liquid filling machine systems enables precise control over filling speeds, allowing operators to optimize throughput based on product characteristics and container specifications. This flexibility ensures that manufacturers can achieve maximum efficiency while maintaining the quality standards required for their specific applications.

Scalable Production Capacity

The scalable nature of automatic filling systems provides manufacturers with the flexibility to adjust production capacity based on market demands. A well-designed liquid filling machine can be easily reconfigured to handle different production volumes, making it an ideal solution for businesses experiencing growth or seasonal fluctuations in demand. This scalability eliminates the need for multiple manual filling stations and reduces the complexity of workforce management.

Many automatic systems feature modular designs that allow for easy expansion by adding additional filling heads or incorporating complementary equipment such as capping and labeling systems. This modular approach enables manufacturers to build comprehensive packaging lines that can evolve with their business needs while maintaining efficient production workflows.

Superior Accuracy and Consistency

Precision filling is critical in industries where product integrity, regulatory compliance, and consumer satisfaction are paramount. An automatic liquid filling machine delivers unmatched accuracy and consistency compared to manual filling methods, ensuring that every container receives the exact volume specified. This precision is achieved through advanced control systems and precision-engineered components that eliminate human error and variability.

Precise Volume Control

Modern liquid filling machine technology incorporates sophisticated volumetric or gravimetric control systems that can achieve filling accuracies within fractions of a milliliter. These systems utilize advanced sensors, flow meters, and control algorithms to monitor and adjust fill volumes in real-time, ensuring consistent results across thousands of containers. The precise volume control is essential for maintaining product quality, regulatory compliance, and customer satisfaction.

The advanced control systems in automatic filling equipment can compensate for variables such as liquid viscosity, temperature fluctuations, and container variations, maintaining consistent fill volumes regardless of external conditions. This adaptability ensures that product quality remains consistent throughout production runs, reducing waste and improving overall efficiency.

Elimination of Human Error

Manual filling operations are inherently susceptible to human error, which can result in underfilled or overfilled containers, product waste, and quality control issues. An automatic liquid filling machine eliminates these concerns by removing human variability from the filling process. The automated systems follow programmed parameters precisely, ensuring that every container receives the correct fill volume without deviation.

The elimination of human error extends beyond just fill volume accuracy to include aspects such as container positioning, timing, and process sequence. Automatic systems ensure that every aspect of the filling process is executed consistently, reducing the likelihood of defects and improving overall product quality. This reliability is particularly important in regulated industries where consistency and traceability are critical requirements.

Significant Cost Reduction Benefits

While the initial investment in an automatic liquid filling machine may seem substantial, the long-term cost benefits make it an economically sound decision for most manufacturers. The cost reduction benefits extend across multiple areas of operation, including labor, materials, and quality control, resulting in improved profitability and competitive positioning.

Labor Cost Optimization

One of the most significant cost advantages of automatic filling systems is the reduction in labor requirements. A single liquid filling machine can replace multiple manual filling operators, dramatically reducing labor costs while increasing production capacity. The reduced labor requirements also eliminate concerns about workforce availability, training costs, and human resource management complexities.

The labor cost optimization extends beyond direct filling operations to include reduced requirements for quality control inspection, rework, and waste management. Automatic systems produce more consistent results, reducing the need for extensive quality checks and minimizing the labor required to address filling errors and defects.

Material Waste Reduction

The precision and consistency of automatic liquid filling machine systems result in significant reductions in material waste. Accurate fill volumes mean less product is wasted due to overfilling, and the consistent performance reduces the number of containers that must be rejected due to filling errors. This waste reduction translates directly to cost savings and improved material utilization efficiency.

Advanced systems also feature spillage prevention mechanisms and efficient product handling systems that minimize product loss during the filling process. These features ensure that expensive liquid products are utilized efficiently, maximizing the value derived from raw materials and improving overall production economics.

Improved Hygiene and Safety Standards

In industries such as food, pharmaceuticals, and cosmetics, maintaining the highest hygiene and safety standards is not just important but mandatory. An automatic liquid filling machine offers significant advantages in maintaining sanitary conditions and ensuring product safety throughout the filling process. These systems are designed with hygienic principles in mind, incorporating features that minimize contamination risks and facilitate thorough cleaning procedures.

Sanitary Design Features

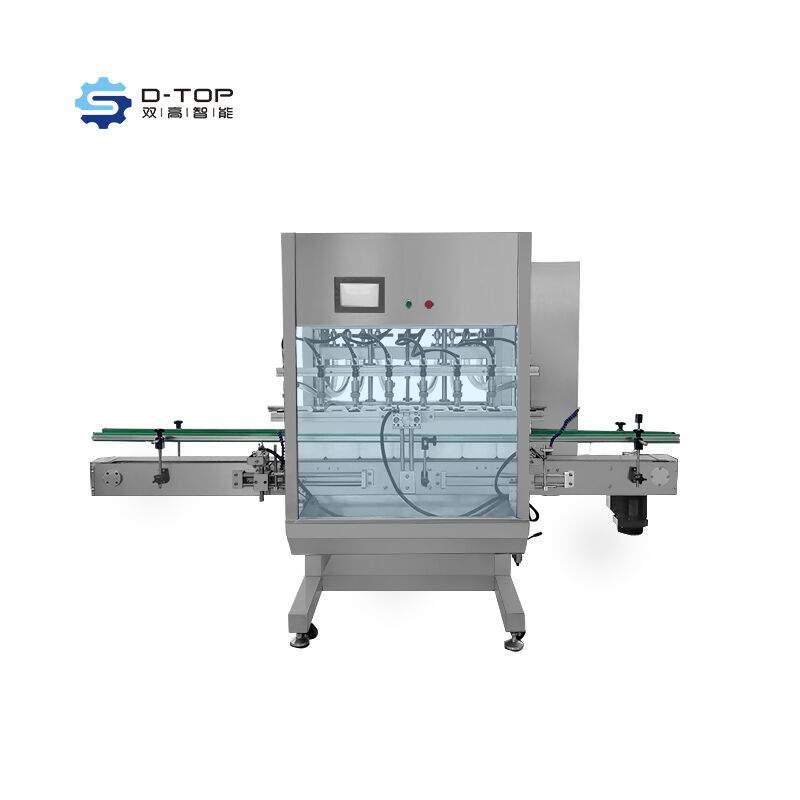

Modern liquid filling machine systems incorporate sanitary design principles that minimize potential contamination points and facilitate effective cleaning and sanitization. Stainless steel construction, smooth surfaces, and minimal dead spaces ensure that these systems meet or exceed industry hygiene standards. The sanitary design features are particularly important for applications involving consumable products where contamination could pose serious health risks.

Advanced filling systems often include features such as Clean-in-Place capabilities, sterile air filtration, and automated sanitization cycles that ensure consistent hygiene standards without requiring extensive manual intervention. These features reduce the risk of product contamination while minimizing the time and labor required for cleaning and maintenance procedures.

Reduced Human Contact

By automating the filling process, liquid filling machine systems significantly reduce human contact with products during the packaging process. This reduction in human contact minimizes the risk of contamination from operators and creates a more controlled environment for product handling. The reduced human interaction is particularly valuable in applications where sterility and purity are critical requirements.

The automated systems also incorporate safety features that protect operators from potential hazards associated with liquid handling, including exposure to chemicals, repetitive strain injuries, and ergonomic issues. These safety improvements create a safer working environment while ensuring consistent product quality and regulatory compliance.

Versatility and Flexibility Advantages

Modern automatic filling systems offer remarkable versatility and flexibility, making them suitable for a wide range of applications and products. This adaptability allows manufacturers to maximize their equipment investment by using a single liquid filling machine for multiple products and packaging formats, reducing capital requirements and improving operational efficiency.

Multi-Product Capability

Advanced liquid filling machine systems can be easily reconfigured to handle different products with varying viscosities, filling volumes, and container types. This multi-product capability eliminates the need for dedicated filling equipment for each product line, reducing capital investment and floor space requirements. The ability to switch between products quickly and efficiently enables manufacturers to respond rapidly to changing market demands and customer requirements.

The multi-product capability extends to handling various container sizes and shapes, from small vials to large bottles, without requiring extensive changeover procedures. This flexibility ensures that manufacturers can diversify their product offerings without significant additional equipment investments, improving their competitive position and market responsiveness.

Customizable Control Systems

Modern liquid filling machine systems feature sophisticated programmable control systems that can be customized to meet specific application requirements. These systems allow operators to create and store multiple filling programs, enabling quick changeovers between different products and filling parameters. The customizable control systems ensure optimal performance for each application while maintaining consistency and quality standards.

The advanced control systems often include data logging and reporting capabilities that provide valuable insights into production performance, quality metrics, and operational efficiency. This data can be used to optimize production processes, identify improvement opportunities, and ensure compliance with regulatory requirements and quality standards.

FAQ

What types of liquids can be processed by an automatic liquid filling machine

Automatic liquid filling machines are designed to handle a wide variety of liquid products, including water-thin liquids, viscous creams, oils, sauces, pharmaceuticals, chemicals, and cosmetic products. The versatility of modern systems allows them to accommodate different viscosities and product characteristics through adjustable parameters and specialized filling mechanisms. Most systems can handle viscosities ranging from water-like consistency to thick pastes, making them suitable for diverse industrial applications.

How often does a liquid filling machine require maintenance

The maintenance requirements for a liquid filling machine depend on factors such as usage intensity, product characteristics, and operating environment. Generally, routine maintenance should be performed daily or weekly, including cleaning, lubrication, and basic inspections. More comprehensive preventive maintenance, including component replacement and system calibration, typically occurs monthly or quarterly. Following manufacturer maintenance schedules and using quality replacement parts ensures optimal performance and extends equipment lifespan.

Can automatic filling systems integrate with existing production lines

Yes, modern automatic liquid filling machines are designed with integration capabilities that allow seamless incorporation into existing production lines. Most systems feature standardized interfaces, adjustable conveyor heights, and compatible control systems that facilitate integration with upstream and downstream equipment such as container handling systems, capping machines, and labeling equipment. Professional installation and system integration services ensure optimal performance and workflow efficiency.

What accuracy levels can be achieved with automatic liquid filling machines

High-quality automatic liquid filling machines can achieve remarkable accuracy levels, typically within ±0.5% to ±1% of the target fill volume, depending on the system type and product characteristics. Volumetric systems generally provide accuracies within ±1%, while gravimetric systems can achieve even higher precision levels of ±0.2% or better. The accuracy depends on factors such as liquid viscosity, temperature stability, and system calibration, but modern systems consistently outperform manual filling methods by significant margins.